Supply chains are vital to manufacturing businesses and the better, more efficient, and more robust your supply chain is, the better your manufacturing operation. Making vital improvements is not that hard, and unless you are investing in a new ERP, you can make them cost-effectively.

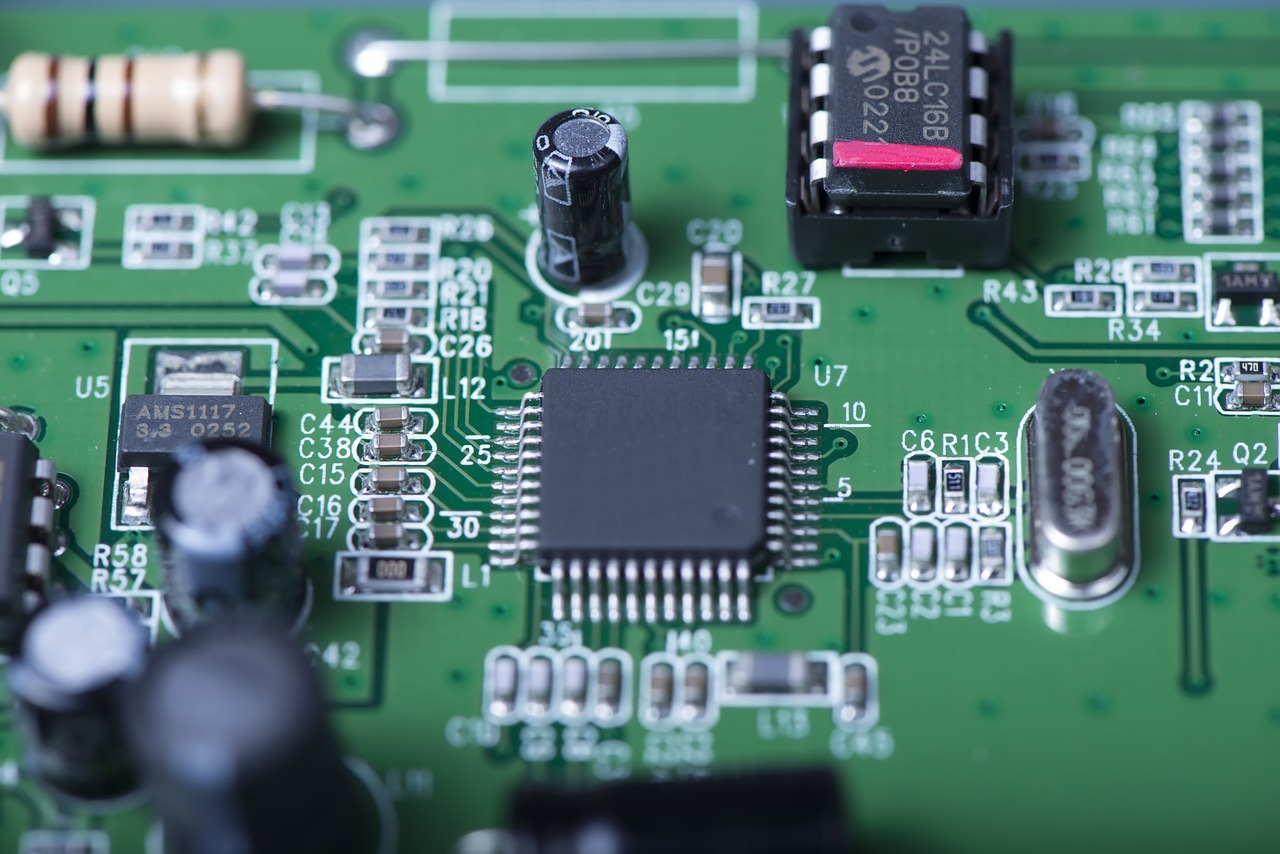

With this in mind, let’s look at tips for improving your industrial electrical supply chain. This will help you ensure stock levels and operate more efficiently.

Internal Communications

Many supply chains hit snags as one internal department doesn’t talk to another. This results in missed opportunities to buy in bulk and subsequently, purchase at a lower price, and it creates far more administration harming productivity.

Consider holding weekly meetings so when you make a big purchase of industrial resistors and other electrical parts, you can place bulk orders.

Consider Transparency

A good ERP system can solve a lot of headaches and remove the need for endless spreadsheets. They have come down in price considerably over the years, and they bring far reaching benefits.

Consider. Would this help you run the business more efficiently?

- More transparency on stock levels

- Automatic reordering of essential components

- Top-down management and permissions system

- Integrated sales and accountancy

- Forward prediction ordering systems as well as retrospective MRP

If you can find the right ERP system that fits your business model, it can solve a lot of headaches. Moreover, you can customize many of the exiting ERP offerings. You may want to consider offering online ordering portals to your customers for better and more efficient integration and supply chain management.

Improve Vendor Management

It is always a good idea to forge solid relationships with your vendors. You can ensure standards are maintained, jump to the front of the queue when you need components to meet an emergency order, and should circumstances change, you will probably get advanced warning.

It also helps when implementing the Perfect Order Index. This was originally developed for retailers. It measures the amount of time you receive parts delivered in good condition with the correct documentation. You can measure and review your vendors in your supply chain. These evaluations can help you identify vendors that perform well and ones that do not. You are now in a good position to make replacements.

Identify Trends

Trend analysis is something to pay attention to. Roughly, your teams will have a good idea of when specific customers will order. This is intuitive and built by experience. If you can make this a more scientific process you have actionable business intelligence. This helps you make better buying decisions and makes your supply chain more reliable.

It also puts you in a better position to negotiate deals making further cost savings and improving efficiency.

One of the key developments in artificial intelligence (AI) is trend analysis.

Final Thoughts

With a more competitive world, it is important you take the time to assess your electrical industrial supply chain and make it as efficient as possible. This will yield higher profits and a more efficient operational business.

You can bet last quarter’s profits your competitors are already doing it.

Site Disclaimer

The Content in this post and on this site is for informational and entertainment purposes only. You should not construe any such information or other material as legal, tax, investment, financial, or other advice. Nothing contained on our Site constitutes a solicitation, recommendation, endorsement, or offer by HII or any third party service provider to buy or sell any securities or other financial instruments.

Nothing in this post or on this site constitutes professional and/or financial advice. You alone assume the sole responsibility of evaluating the merits and risks associated with the use of any information or other content in this post or on this site.

You recognize that when making investments, an investor may get back less than the amount invested. Information on past performance, where given, is not necessarily a guide to future performance.

Related Categories: Work, Reviews, Tech