What Is Fiber Laser Cutter?

Fiber laser cutting machine is an excellent, high velocity, high-accuracy, high-effectiveness CNC laser metal cutting framework. It is reasonable for a wide range of metal cutting and is your great metal handling accomplice. Fiber laser cutting machine is otherwise called fiber laser metal cutting machine, fiber laser cutting machine, fiber laser cutting framework, and fiber laser cutting hardware.

What Is Fiber Laser Generator?

Fiber laser generator alludes to a laser generator that utilizes uncommon earth component doped glass fiber as the increase medium. Its attributes are impacted by the progress properties of the optical fiber. Different siphon modes contrastingly affect different sign modes. Making the investigation of fiber laser generators and intensifiers more muddled. The created unconstrained outflow light goes through excitation intensification and mode determination of the full cavity to shape a steady laser yield.

How does a thunder laser respond?

One of the most amazing elements of Thunder Lasers is their smooth speed. In only one moment, a standard laser shaper can cut around 8 meters of material — a 1,000 watt machine might in fact arrive at paces of 17 meters each moment.

What Are The Features Of Fiber Laser Cutters?

- Fiber laser has high electro-optical change effectiveness.

- The fiber laser embraces semiconductor modularization and repetitive plan. There is no optical focal point in the resonator, and there is no beginning up time. It enjoys the benefits of change free, upkeep free and high security. It decreases embellishment expenses and upkeep time.

It right away melts and disintegrates the illuminated region on the workpiece surface. The spot is centered finely and moved by a CNC mechanical framework. The light position acknowledges programmed cutting. Contrasted and massive gas lasers and strong state lasers, it enjoys clear benefits. It has steadily formed into a significant competitor in the fields of high-accuracy laser handling, LIDAR frameworks, space innovation, and laser medication. Reasonable for high-accuracy cutting of metal plates, and so on. Contrasted and conventional carbon dioxide laser cutting machine, fiber laser machine saves space and gas utilization, and has high photoelectric transformation rate.

Learn more there are some major benefits of fiber laser cutters are as follows;

- High precision:

laser shaper situating precision is 0.05mm, and continued situating exactness is 0.03mm.

- The cut is thin:

With the generally direct development of the bar and the material, the opening consistently frames a cut with an exceptionally limited width. The width of the cut is for the most part 0.10-0.20 mm.

- The cutting surface is smooth:

The cutting surface has no burrs, and the harshness of the cut surface is for the most part controlled inside Ra6.5.

- Fast:

The cutting pace can reach 10m/min, and the most extreme situating rate can reach 30m/min.

- Top caliber:

Non-contact cutting, the forefront is impacted by heat very little.

- No harm to the workpiece:

The Laser engraving head won’t in touch with the outer layer of the material to guarantee that the workpiece isn’t damaged.

- Not impacted by the state of the workpiece:

Laser handling has great adaptability, can deal with any designs, and can cut pipes and other molded materials.

- Save form speculation:

Laser handling requires no form, no shape utilization, no shape fix, saving mold substitution time.

- Material saving:

Utilizing PC programming, results of various shapes can cut boost the use pace of materials?

- Security and ecological insurance: laser handling waste is low; commotion is low, perfect, safe and contamination free, enormously working on the workplace.

What advantages could you at any point get from laser cutting? – benefit

Laser cutting will supplant conventional mechanical cutters with undetectable laser radiates. It enjoys the benefits of high velocity, superior grade, not restricted by cutting examples, and programmed typesetting to save materials, smooth front lines, and low handling costs. The Fiber Laser Cutting Machine interaction will bit by bit improve or supplant the conventional cutting cycle. The intensity impacted zone is little, and the disfigurement of the plate is little.

The cut has no mechanical pressure and no shear burrs. High accuracy, great repeatability, no harm to material surface, smooth forefront. Utilizing CNC programming, any plane can machined without structure

Instructions to DIY A Laser Cutter?- Building Guide

A total laser cutting machine comprises of laser generator, cutting head, shaft transmission parts, cutting table, CNC regulator, cooling framework and other center parts.

Laser Generator

A laser generator is a part that creates a laser light source. For metal cutting, fiber laser generators are proficient. For non-metal etching and cutting, CO2 laser generators are the most appropriate decision.

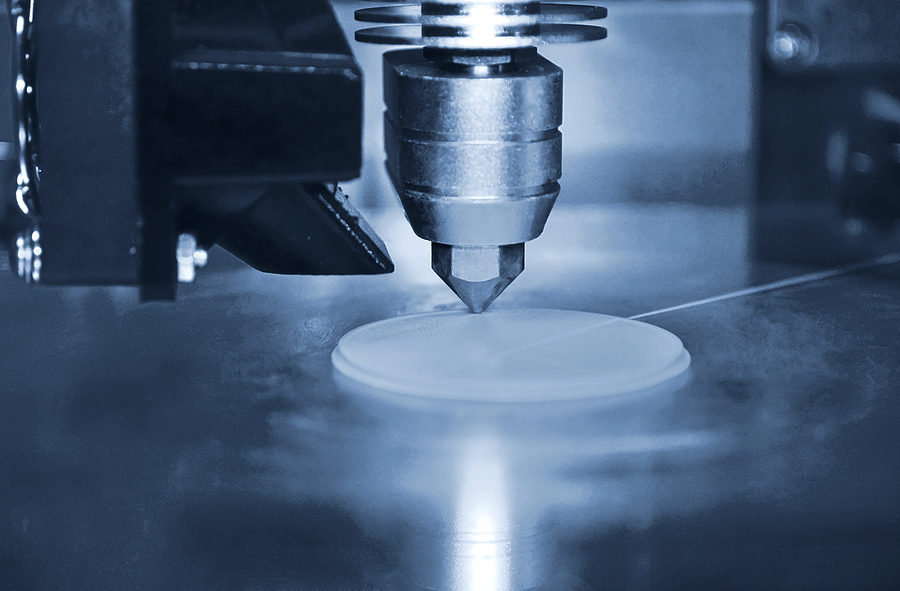

Laser Cutting Head

Centering focal point and a centering global positioning framework.

Spout

There are three normal sorts of spouts available: equal, uniting and funnel shaped.

Centering Lens

Center the energy of the laser bar and structure a high energy thickness spot. The medium and long centering focal point is reasonable for thick plate cutting, and has low necessities on the dividing soundness of the global positioning framework. The short centering focal point is just reasonable for slender plate cutting, which requires high dividing soundness of the global positioning framework and extraordinarily lessens the laser yield power necessities.

Center Tracking System

The sensor is made out of detecting component and intensification control part. The global positioning framework is totally unique as indicated by the different detecting components.

Image Source: BigStockPhoto.com (Licensed)

Site Disclaimer

The Content in this post and on this site is for informational and entertainment purposes only. You should not construe any such information or other material as legal, tax, investment, financial, or other advice. Nothing contained on our Site constitutes a solicitation, recommendation, endorsement, or offer by HII or any third party service provider to buy or sell any securities or other financial instruments.

Nothing in this post or on this site constitutes professional and/or financial advice. You alone assume the sole responsibility of evaluating the merits and risks associated with the use of any information or other content in this post or on this site.

You recognize that when making investments, an investor may get back less than the amount invested. Information on past performance, where given, is not necessarily a guide to future performance.

Related Categories: Tech, Reviews