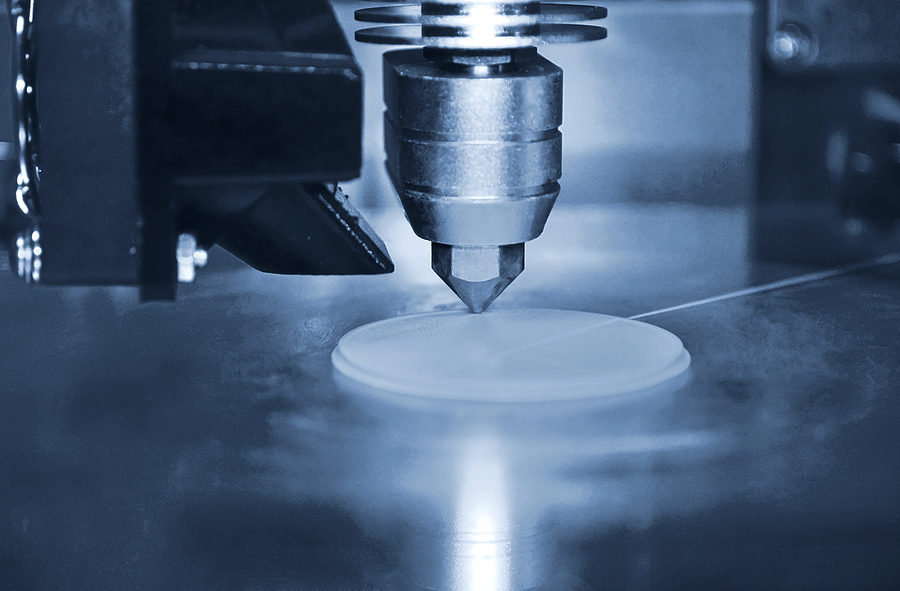

Custom machining, speaks accurately, refer to the custom CNC machining services in order to meet a customer’s specific requirements for piece-parts or component parts. Ordering tailored components from an online machine shop have become a kind of popular trend thanks to the high speed of CAD modeling, rapid internet, and, global shipping.

The Importance of Custom Machining

Table of Contents

- CNC machining uses the CAD files from designers and converts them to the program is commanded by software. For the CAD files, it is flexibly changed and can be designed according to the customer requirement.

- Lots of materials can be used by CNC machining, including the plastic and metal, which can meet the custom machining requirement, let alone so many post finish process can provide the one-stop custom services.

- Shorten lead time. Time is money, for the custom machining, it is more important because the quicker get the custom parts, the earlier to occupy the market. In view of this, more and more CNC machine shops use the online quote system, to save time and receive the parts quickly.

- No MOQ (minimum order quantity) limitation. Not like the plastic injection molding, the CNC machining can produce a single part, which largely meets the custom machining.

Types Of Custom Machining Method

When people need custom production parts, it means that the parts may be not standard or it has a complex structure and unique features. A CNC machine shop can provide so many technology methods to meet the custom machining.

- CNC milling

- CNC turning

- EDM/Wire EDM

Normally, the CNC milling and CNC turning can implement a lot of features’ custom machining, these parts can be contours, grooves, complex rotary shape, inner hole, thread, bite flower, and so on. However, when it comes to the complicated structures such as punch, die, convex and concave die, fixed plate, unloading plate, micro-hole slot, narrow slot, etc., EDM is the best choice for your custom machined parts, especially for the big radius at the corners caused by the CNC machining, for which it can clear the radius and keep right angle.

When the custom machining not just requests the individuation, the high quality is getting more and more important, the machine shops start to configure 5-axis CNC machining capacity, which can support multifaceted parts with tight tolerances. It is also called the custom precision machining, and you can get the final parts with high accuracy and short lead time.

Different Ways of Custom Machining Services

1. Custom Prototype Machining Services

When it comes to the prototype, the product development process immediately comes to mind as below:

POC(proof of concept)→EVT(engineering validation)→DVT(Design validation)→PVT (production validation)→MP(mass production)

If you have a design idea, you must want to have a model to show your team or potential customers. In order to get more support, prototyping is the best way. Whatever it is a proof of concept prototype, visual display prototype, functional prototype, or engineering prototype, custom machining can provide the complete services throughout the whole product development while cooperating with the continuous improvement and optimization of the design until your design is decided.

2. Custom Low Volume Machining Services

As we all know the end of product development is mass production, which means the design and manufacture all are locked down, and the real tooling will be created. But if there are still some design errors that exist, it means the huge loss.

So, more and more CNC machine shops provide the custom low volume machining services, which can narrow the bridge between prototype and production. Why is it so popular?

- Cost-effective. You do not need to invest the expensive tooling.

- Quick turnaround.

- The quantity is not so big but enough to re-validate the design and production and give you more confidence in mass production.

- The quality is the same as mass production parts’, you can launch the low volume custom parts to market to collect customer feedback.

3. Other Custom Services

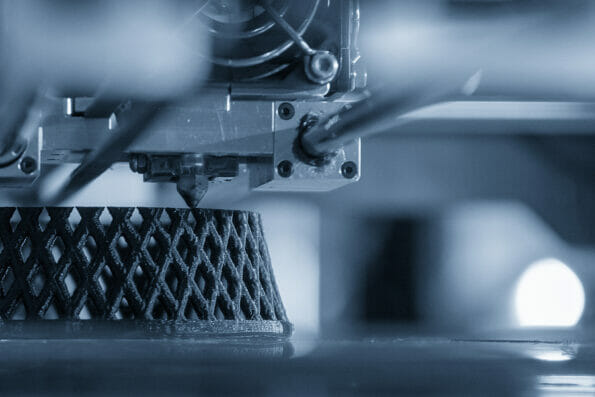

In the rapid prototyping industry, besides the custom machining, there are many other popular custom services, such as 3D printing, vacuum casting, rapid injection molding, etc., they all have their pros and cons.

- 3D printing: plastic and metal. It is quick and can create complex geometries. But the accuracy is not as good as the CNC machining, and sometimes the materials are expensive.

- Vacuum casting: Only plastic. It is low cost and can be used for low volume manufacturing, but when the parts quantity increases, the silicon mold quantity also increases, and then the cost is not low.

- Rapid injection molding: Only plastic. When you need a large quantity such as hundreds to thousands of prototypes custom services, it is cost-effective and you can get the same quality as the mass production.

Conclusion

Custom machining plays an important role in the rapid prototyping industry, you can get benefits from custom prototype machining and custom low volume machining services, which throughout your entire product development process. Take custom machining for modern robots as an example.

A good CNC machine shop also provides other custom services, such as the 3D printing, vacuum casting, rapid injecting, etc,

Image Source: BigStockPhoto.com (Licensed)

Site Disclaimer

The Content in this post and on this site is for informational and entertainment purposes only. You should not construe any such information or other material as legal, tax, investment, financial, or other advice. Nothing contained on our Site constitutes a solicitation, recommendation, endorsement, or offer by HII or any third party service provider to buy or sell any securities or other financial instruments.

Nothing in this post or on this site constitutes professional and/or financial advice. You alone assume the sole responsibility of evaluating the merits and risks associated with the use of any information or other content in this post or on this site.

You recognize that when making investments, an investor may get back less than the amount invested. Information on past performance, where given, is not necessarily a guide to future performance.

Related Categories: Tools, Reviews, Work